Wire Mesh Cable Trays

- Home

- Products

Wire Mesh Cable Trays

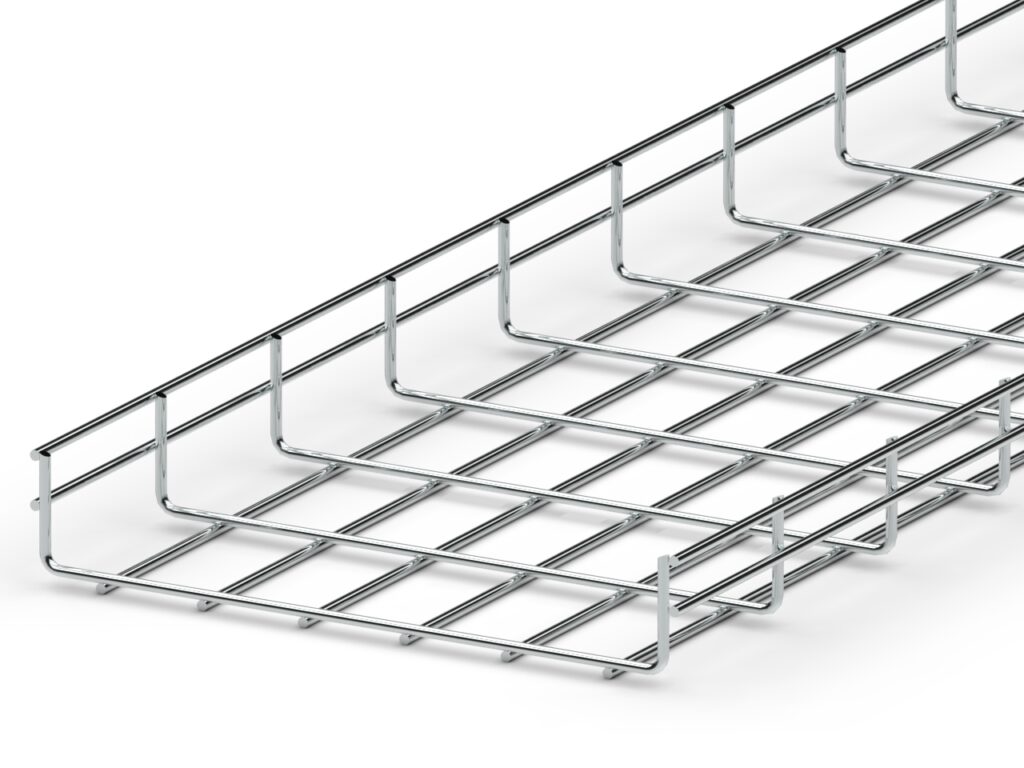

Introduction: Efficient Cable Management with Wire Mesh Cable Trays

Understanding Wire Mesh Cable Trays

Document Detail

Straight Mesh

Straight wiremesh cable trays are known for their simplicity and straightforward design. They consist of straight sections of wiremesh that are easy to install and maintain. Some key features and benefits of straight wiremesh cable trays include :

Simplicity: Straight wiremesh cable trays are easy to understand and install.

Versatility: They can be used in various settings and configurations.

Cost-Effective: These trays provide an economical cable management solution.

Durability: They are designed to withstand harsh conditions and ensure long-lasting performance.

Wave Mesh

Waved wiremesh cable trays are designed with a wavy pattern, which offers some unique characteristics :

Enhanced Cable Support: The waved design provides better support for cables, reducing sagging.

Improved Ventilation: Waved trays allow for better airflow around the cables, preventing heat buildup.

Aesthetics: Some users prefer the aesthetic appeal of waved wiremesh trays.

Advantages

Efficient Cable Ventilation

The open design of wire mesh cable trays allows for optimal airflow, preventing the accumulation of heat and promoting cable performance and longevity.

Flexible Cable Routing

The wire mesh pattern offers flexibility in routing cables, accommodating various cable sizes and types. This makes wire mesh cable trays suitable for managing power cables, data cables, and communication cables.

Enhanced Visibility

The open wire mesh design provides excellent visibility of the cables, enabling easy identification, tracing, and maintenance, thereby reducing downtime during troubleshooting or repairs.

Lightweight and Cost-Effective

Wire mesh cable trays are lightweight, which simplifies installation and reduces the overall system weight. Additionally, they are a cost-effective solution compared to other cable management systems.

Available Options

Electro Galvanized, Hot-Dip Galvanized, Stainless Steel 304, Stainless Steel 316, Powder Coated .

Our wire mesh cable trays are available in various material options to suit different project requirements:

Electro Galvanized

These trays are coated with a layer of zinc through the electro-galvanization process, providing corrosion resistance and durability for indoor applications.

Hot-Dip Galvanized

Hot-dip galvanized trays undergo a specialized coating process, resulting in superior corrosion resistance, making them suitable for outdoor or harsh environments.

Stainless Steel 304

Stainless steel trays (SS304) offer excellent corrosion resistance, durability, and hygiene, making them ideal for demanding environments such as food processing facilities and hospitals.

Stainless Steel 316

Stainless steel trays (SS316) provide enhanced corrosion resistance, making them suitable for highly corrosive or marine environments.

Powder Coated

Powder coated trays are steel trays coated with a durable powder finish, providing additional protection against corrosion, abrasion, and UV rays. They are commonly used in commercial and industrial settings.

Common Applications Used

FAQs