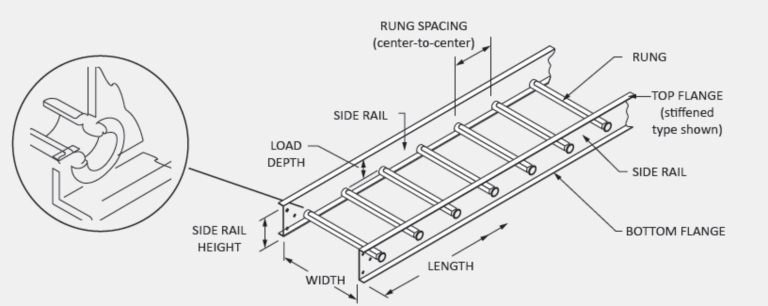

Ladder Type Cable Tray

- Home

- Products

Ladder Type Cable Tray

Introduction: The Importance of Cable Management

Document Detail

Features of the New Model

1. Embossed Design: The embossed design of the cable tray offers various technical benefits.

The embossed design features ridges and grooves that help secure the cables in place. This minimizes the risk of cables shifting or becoming disorganized, ensuring a neat and organized cabling system.

2. Rolled Flange for Extra Strength: Rolled Flange for Extra Strength.

The rolled flange reinforces the cable tray's structure, preventing sagging or bending over time. This structural integrity is crucial for maintaining the integrity of the cabling system.

3. No Welding: The absence of welding in the new Ladder cable tray model offers the following advantages.

Welding joints are often susceptible to corrosion, which can compromise the longevity of traditional cable trays. The absence of welding in this model enhances its durability, reducing the need for maintenance and replacements.

XS Series

What is XS?

- eXtra Strength

- eXtra Stability

- eXtra Safe

eXtra Strength

eXtra Stability

eXtra Safe

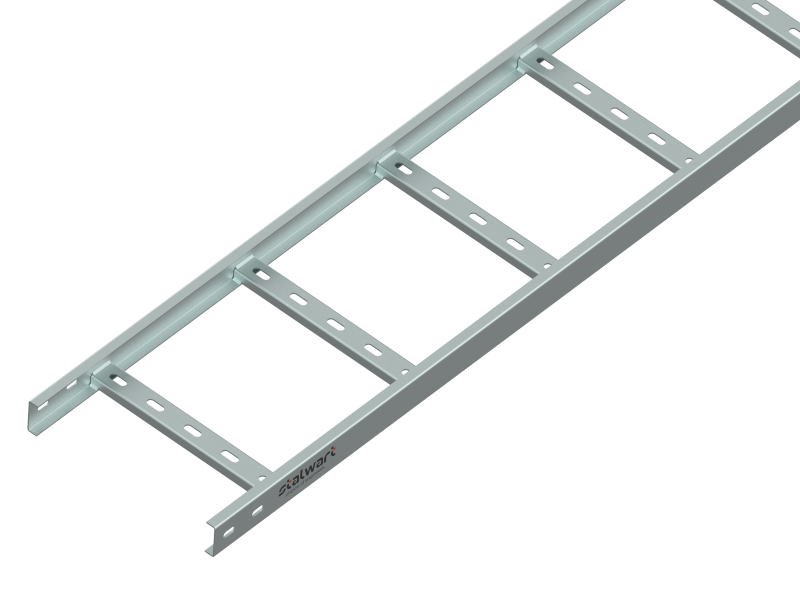

Emboflange Series

The Emboflange Ladder cable tray model offers a trifecta of technical benefits that revolutionize cable management. Its rolled flange not only bolsters its load-bearing capacity, making it ideal for heavy-duty applications, but also enhances its overall durability, reducing maintenance costs and ensuring long-term reliability. Meanwhile, the embossed design provides an elegant touch while significantly improving the cable tray’s structural integrity, offering cable security, and increased rigidity. Additionally, the absence of welding eliminates the risk of defects, streamlines installation, and extends the tray’s lifespan, resulting in a versatile, resilient, and cost-effective cable management solution.

What is Emboflange ?

- Extra Strength

- Embossed Excellence

- Rolled Flanged

Extra Strength

Embossed Excellence

Rolled Flanged

Standard Series

The Standard Ladder type Cable Tray is a well-established solution for cable management. Its open design, characterized by parallel bars forming a ladder-like structure, offers excellent ventilation, reducing the risk of cable overheating. This design allows for easy access to cables for maintenance and adjustments. Standard Ladder trays are widely used in various industries due to their simplicity, cost-effectiveness, and adaptability to different environments. They are a reliable choice for routing and supporting cables in a structured and organized manner.

Advantages

Embossed Design

The embossed pattern enhances structural strength and cable security while adding an elegant touch.

Rolled Flanges

Rolled flanges provide extra strength and durability, ideal for heavy loads and long-term use.

No Welding

The absence of welding eliminates the risk of defects, streamlines installation, and extends the tray's lifespan.

Enhanced Cable Protection

The open rung design of ladder type cable trays allows for proper air circulation, preventing cable overheating. This design also enables easy identification, access, and maintenance of cables.

Technical