Slotted C Channel

- Home

- Products

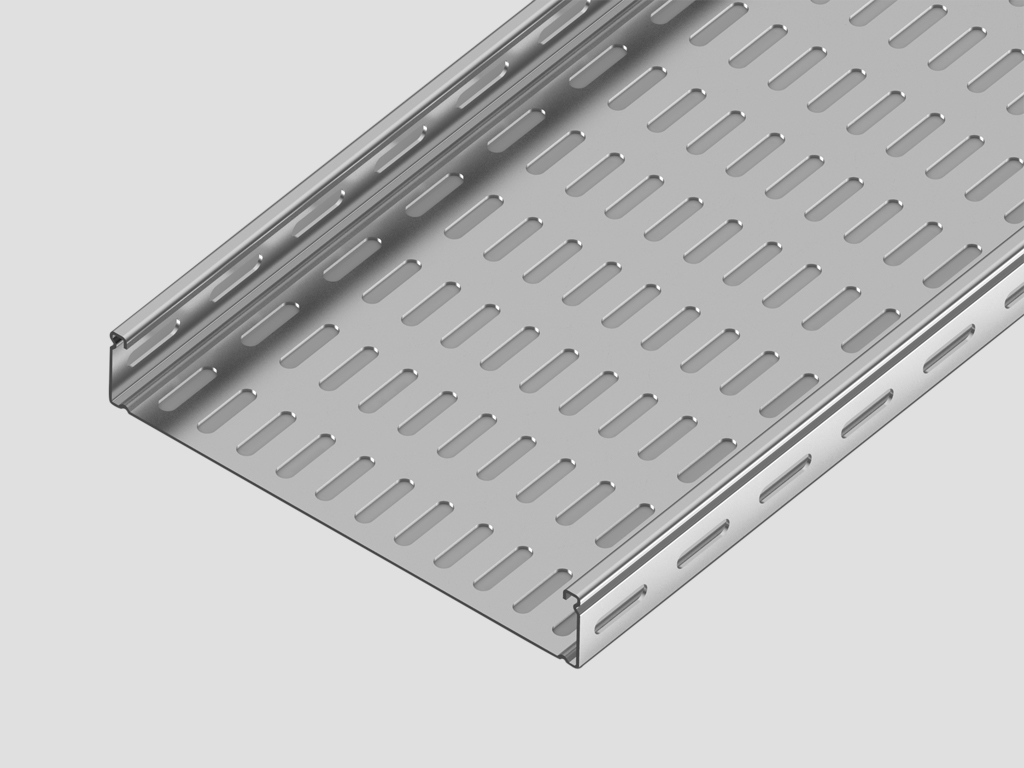

Slotted C Channel (Double Bended)

Looking for a cable tray support system that stands out in terms of strength and versatility? Our Double Bended C Channel is the solution you’ve been searching for. Here’s why it’s a game-changer for your cable management needs :

- Unmatched Stability : The double-bended design isn’t just about aesthetics; it adds an extra layer of stability, ensuring your cable trays remain secure even in demanding conditions.

- Heavyweight Champion : With an exceptional load-bearing capacity, it’s more than capable of supporting heavy cables and trays, making it an ideal choice for diverse applications.

- Structural Integrity : Our C channels are designed to enhance the structural integrity of your support system, promoting long-term reliability and safety.

- Versatile Customization : The double bended C channel is as versatile as it is robust. It’s slotted for easy adjustments, allowing you to customize it to meet your unique project requirements effortlessly.

- Streamlined Cable Routing : Enjoy efficient and organized cable routing with the slotted design, preventing cable damage and maintaining an orderly cable tray system.

- Built to Last : Crafted from durable materials, our Double Bended C Channel ensures longevity and durability, making it a wise investment for your infrastructure.

Complete Installation Guide :

Materials and Tools Needed :

- Full threaded rods

- C channels

- Nuts and washers

- Appropriate fastening tools (wrenches, pliers)

- Measuring tape

- Level

- Drill and anchors (if attaching to a wall or ceiling)

- Safety gear (gloves, safety glasses)

Slotted Strut Channels

Single strut channels, also known as single slotted channels, are the most basic type of strut channels. They feature a single continuous slot on one side, which allows for easy and versatile attachment of various components.

Technical Specifications :

- Material: Typically made from steel, aluminum, or stainless steel.

- Sizes: Available in a range of widths and lengths.

- Slot Dimensions: The slot dimensions can vary, but they are typically standardized for compatibility with a wide range of accessories.

Solid Channels

Solid channels, as the name suggests, have no slots. They are used when a continuous, uninterrupted surface is required for support, such as for structural beams or as a base for other accessories.

Technical Specifications :

- Material: Typically made from steel or aluminum, and occasionally stainless steel.

- Sizes: Available in various sizes and thicknesses.

- No Slots: Unlike slotted channels, solid channels have a flat, solid surface with no openings.

Slotted C Channel (Double Bended)

Installation Steps

- Determine the precise locations where the threaded rods will be installed to support the cable trays.

- Ensure that these locations are suitable and can bear the weight of both the cable trays and the cables.

- Use a measuring tape and mark the spots where the rods will be placed.

- Ensure the distances between each rod are according to your cable tray specifications and system requirements.

- If installing on walls or ceilings, drill holes where you've marked the spots. Use anchors to secure the holes if the material is not strong enough to hold the weight.

- Attach the C channels to the full threaded rods. The channels should be perpendicular to the rods and at regular intervals to support the cable trays effectively.

- Insert the full threaded rods through the C channels.

- Attach nuts and washers to the threaded rods on both sides of the C channel. Ensure that the nuts are tightened securely to hold the rod and the C channel in place.

- Use a level to ensure that the C channels are aligned horizontally or according to your project's requirements.

- Once the rods and C channels are securely in place, lay the cable trays on top of the C channels.

- Ensure that the trays are level and supported evenly by the C channels.

- Double-check the alignment, levelness, and the overall stability of the cable trays.

- Tighten any nuts or bolts as necessary to secure the entire system.

- Inspect the installation for any signs of weakness, instability, or misalignment.

- Ensure that all connections are secure and that the cable trays are safe for use.

C channels are commonly made from materials like steel, aluminum, or other metals with high strength and durability.

Yes, C channels are often used in outdoor applications, but proper measures should be taken to prevent corrosion.

Yes, C channels are widely used for load-bearing purposes due to their robust construction and strength.

Consulting with structural engineers or industry professionals can help determine the appropriate sizing for your project.

Yes, C channels are commonly used in residential construction for various structural and framing applications.